Paul/anybody

Can you suggest a strategy for the following scenario. One assembly is used for many similar products by varying parameters in its Equation Manager. The desired output is a set of shop drawings which should take a morning to produce for each job in the workshop.

Assembly TypeA-small-101 is fabricated from standard structural shapes of varying lengths with lengths derived from the equation manager. There may be parts PFC-075-001, PFC-075-002,…PFC-075-011 each differing only in length plus many other sections. Part PFC-075-001 can only be used in TypeA-small-101 because its length is [TypeA-small-101.Z3ASM:Member1]. Configurations are not favoured because one part could have several configurations in one assembly and the mass changes when all the lengths in the Equartion Manager are changed must be edited in any subassembly and can lead to error. Many snapshots (jobs) of TypeA-small-101 can be generated sequentially by changing the main values in the Equation Manager and generating drawings from the current snapshot but this means that only the latest version is available as the previous snapshot is overwritten. I want to keep the snapshots as an as built record without having to create new parts for each iteration. If a copy of the assembly is archived, it must keep its name and file location which is not possible. If a package of the parts and assembly is archived, there must be flexibility in file location reference to enable the model to be opened later.

Any suggestions as I cannot see how to do this keeping to fixed file locations and there will be many copies of part PFC-075-001 and all other parts? There could be a copy of TypeA-small-101 package in archive Job_11 and in archive Job_23 etc.

Jim

Understand the problem but not the solution !

I know your pain.

It is really a configuration challenge but configurations can only work reliably at one level deep. Well that was my experience in 2020 and I’m not aware of any great advances since. Could be I’m wrong.

Other software creates files for every config then uses those but that becomes a monster in its own right.

So a great question will need a great answer.

Cheers Paul

In multi-object files it was easy as all references were kept in one file and the file was just copied to archive folders Job_22, Job_24 etc where the data was frozen as the archive folders were outside ZW3D’s search paths.

Jim

HI Jim159:

I hope you can give me a demo project file and package it for me to test. Thank you!

我希望你能给我一个演示项目文件,打包给我以便测试,谢谢!

Hi Jim

I have not tried this with Z3 yet, but this is how we manage $olidWorks at work, no PDM or Vault

Anyone jump in if this does not work…

‘Assembly’ TypeA-small-101 and all its associated parts are saved in a common folder with a naming convention similar to Paul’s, when the assembly is working correctly, we set that folder to read only.

For a new customer/job, we copy and rename the top assembly and its drawing to the job folder.

The Assembly does not actually contain parts, just links to parts (configured) and how they are constrained.

When we open this Assembly all the internal links point back to the original parts.

We can delete parts, change part configurations and add customer specific parts in this Assembly without affecting the Original.

Because the drawing is linked to the assembly, it is mostly done, depending on how much the new configurations fit on the sheets.

The reason for setting the Original folder to ‘read only’ is key to not accidentally modifying the original parts or assemblies, and gives us the prompt to ‘Save As’ the part or assembly as a new revision or job specific part.

Each Customer or Job now has it’s own Job Specific Assembly and Drawing, we PDF all parts and assemblies, just in case.

There are no duplicate parts, the Job folder has one Assembly and Drawing and a bunch of PDF’s.

One thing to note is, the Top Assembly has only parts and Assemblies, no nested assemblies(unless they are very small) this makes it very easy to customize each job.

Cheers

Wayne

Thanks Wayne

I use my client’s licence and this exercise is to build a case to upgrade to ZW3D 2022 so I am doing this on an evaluation copy. The shop works on major sub-assemblies which are assembled into the finished job. I can build this model with 3 levels, Assembly, Major sub assembly and part as it is convenient to organise the drawings in the same way as the shop is organised. I will build a model for Liangfen but with the time constraints some of the sub-assemblies may be incomplete. I have 14 days left on the evaluation copy.

Jim

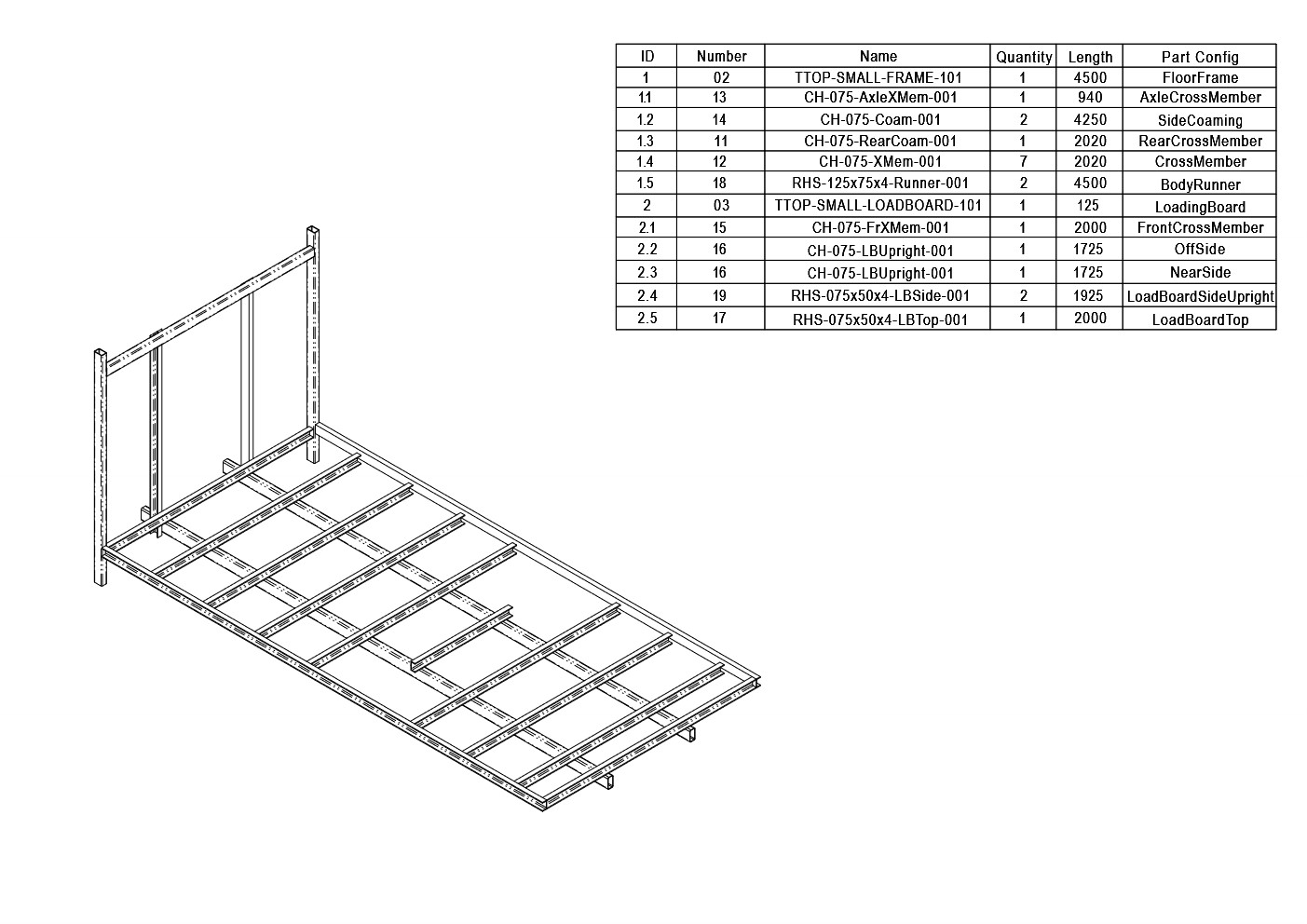

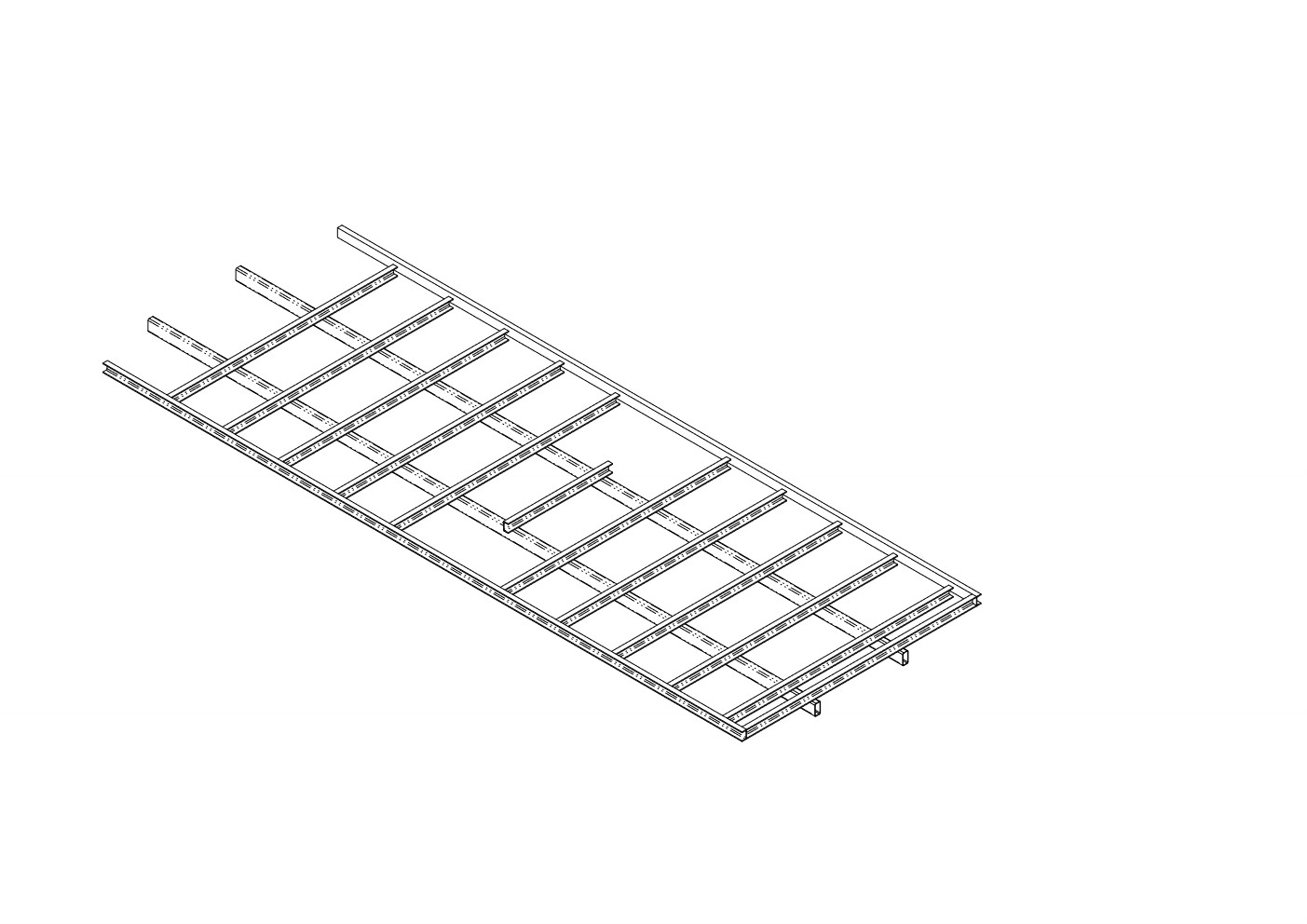

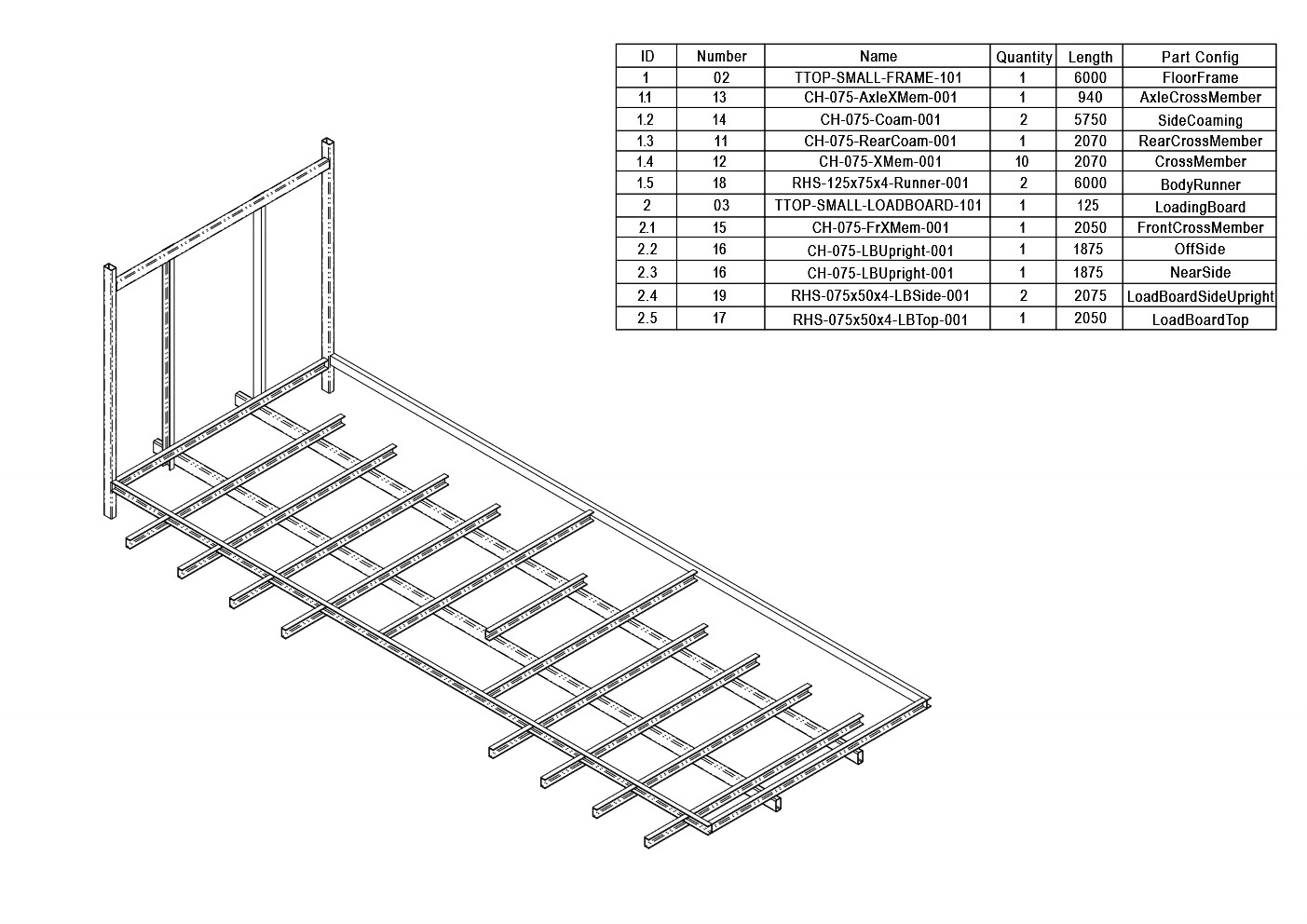

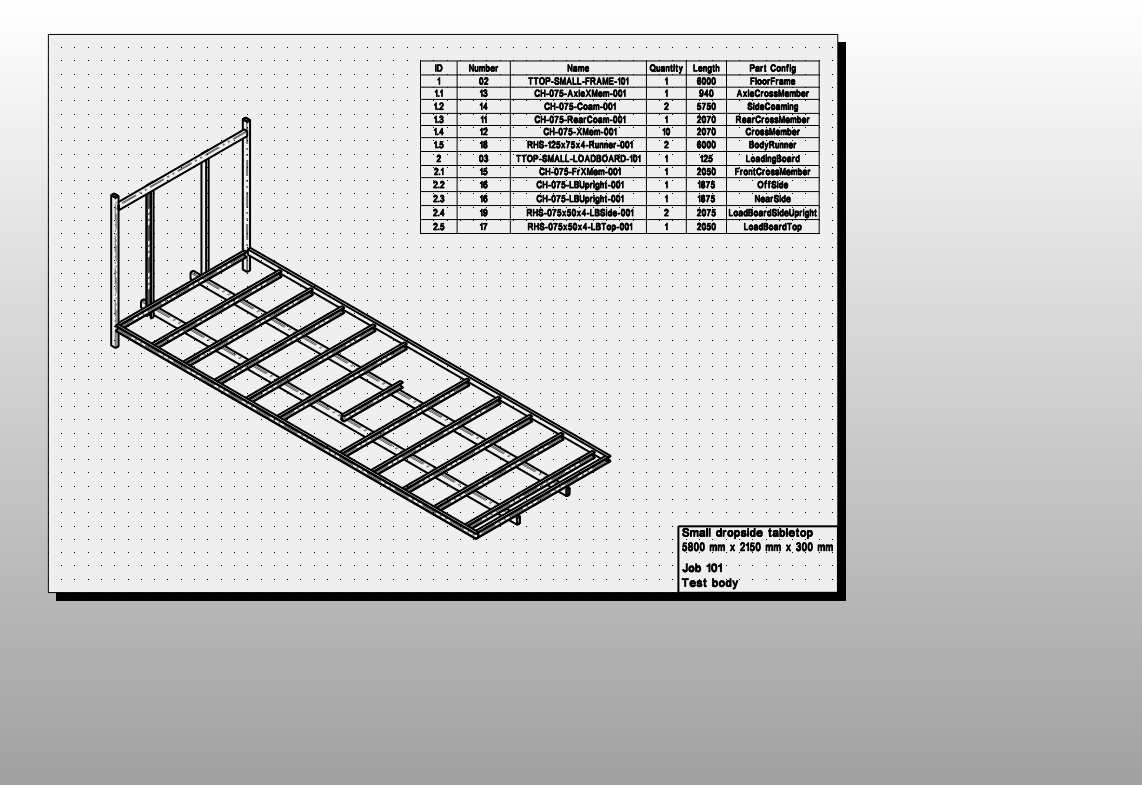

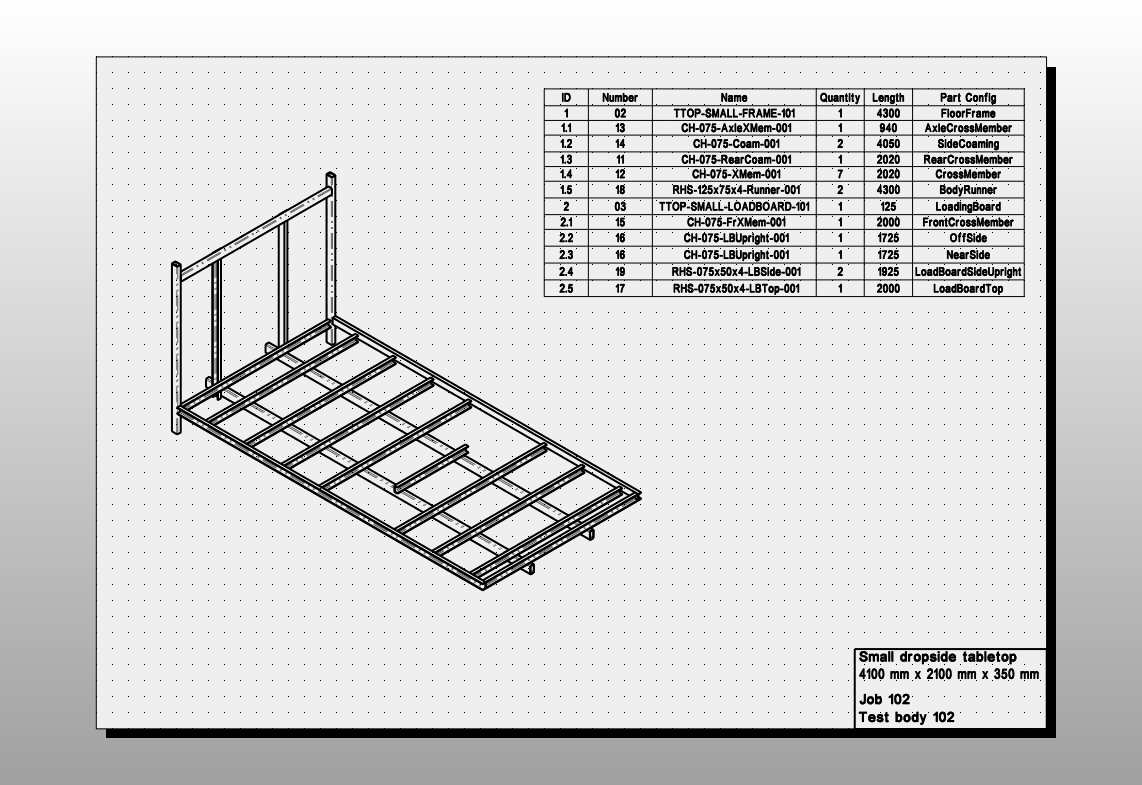

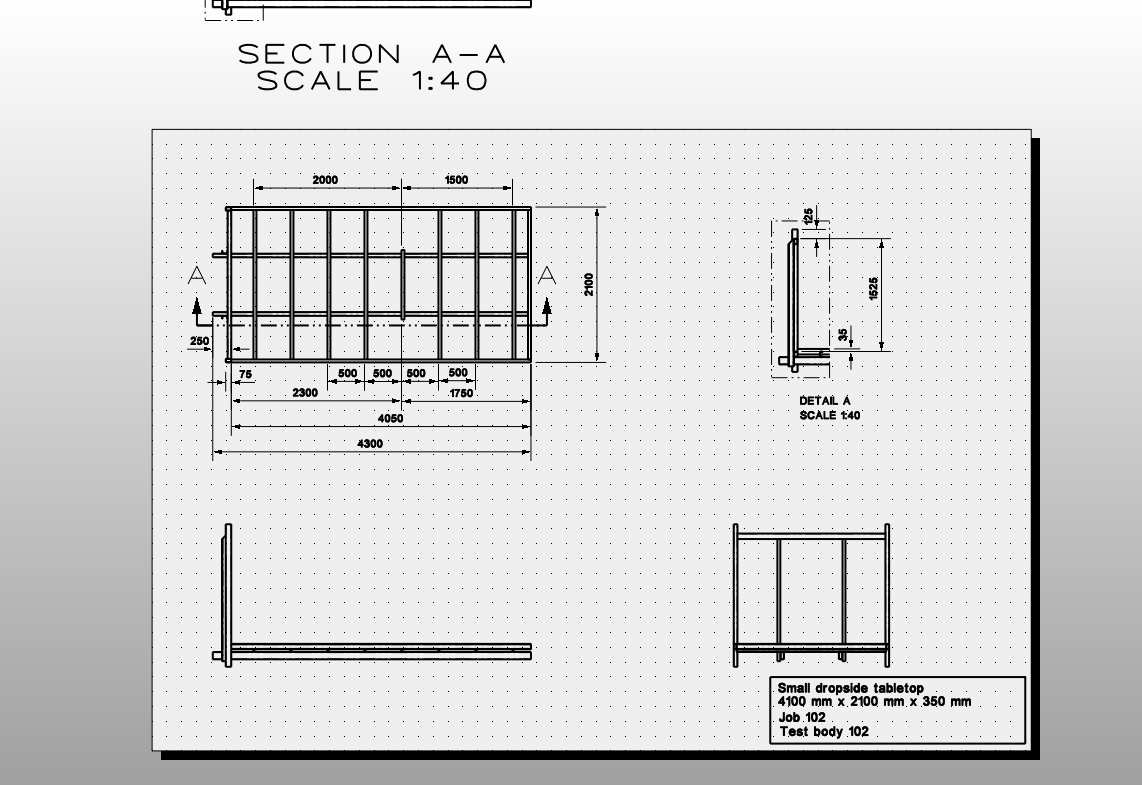

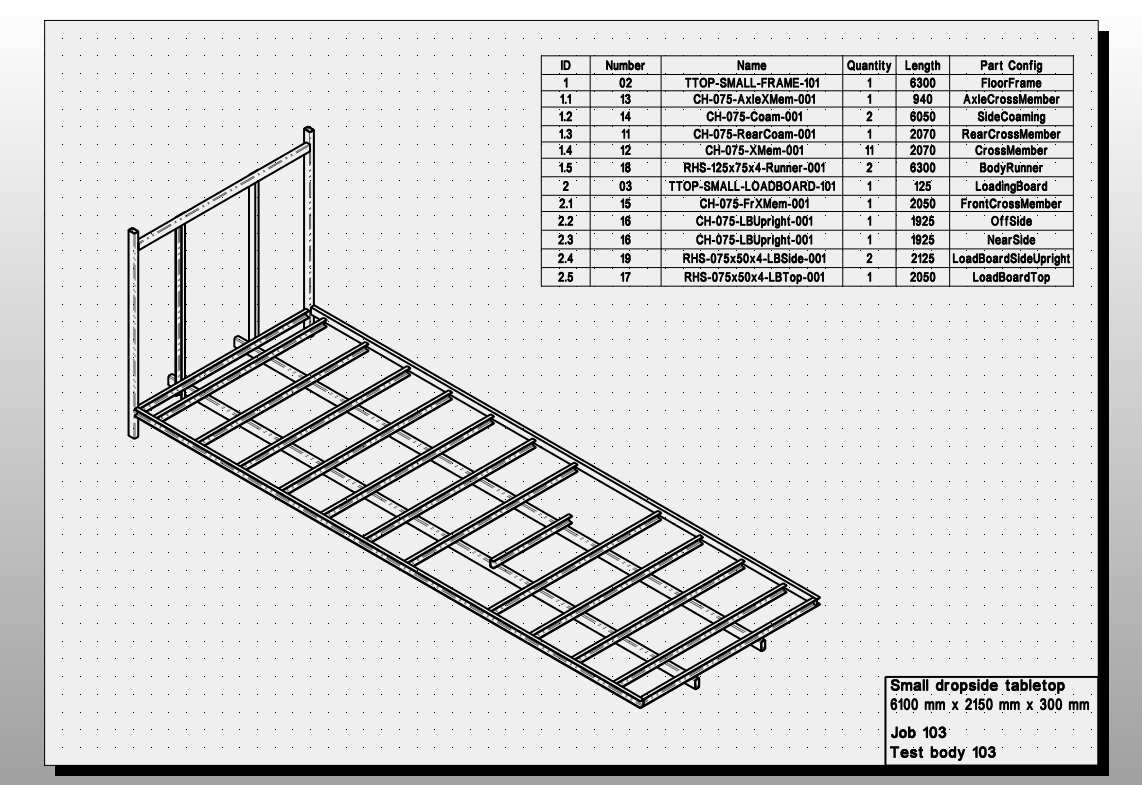

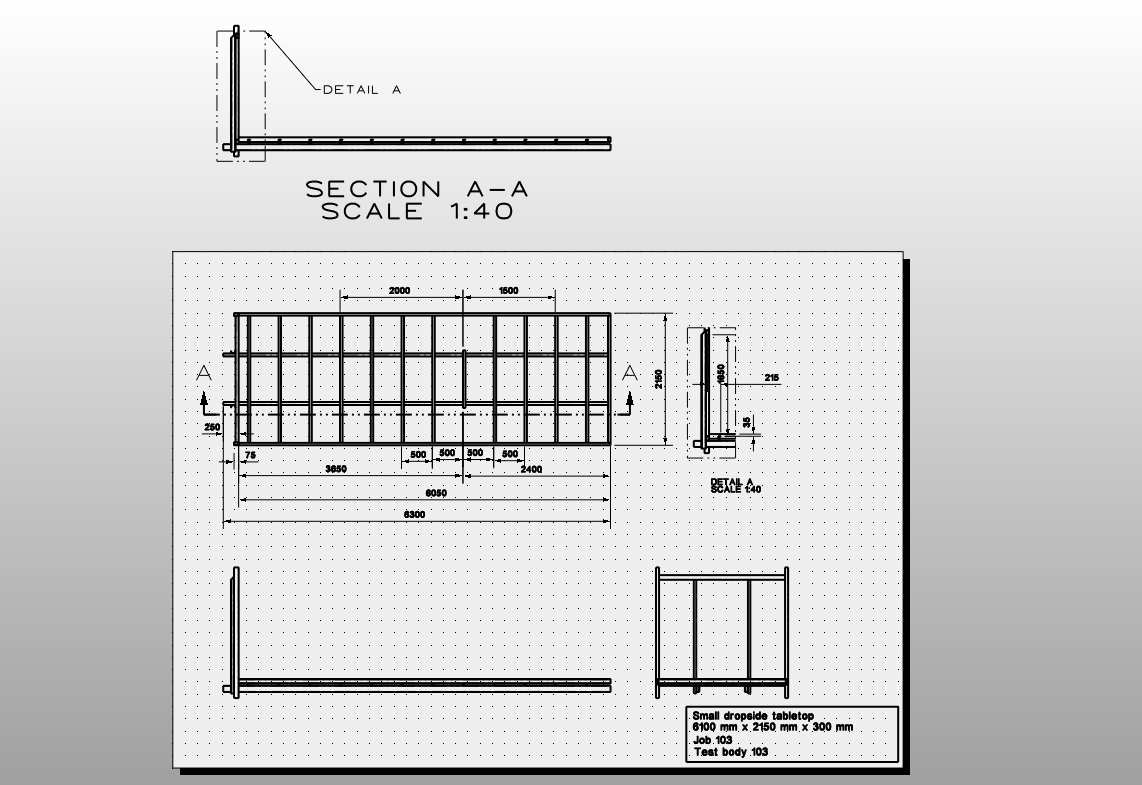

Well, I have built a quick and dirty model for Lianfen. It is only a small part of the truck body design but should get the message across. There are floor sheets which the model calculates length and width and there can be 1, 2 or 3 dropsides per side depending on truck length of a height specified in the Equation Manager. As I said, it is pretty dirty, I have not put much thought into part numbering but found numbers only very difficult to use building the assembly where there are several versions of one part.

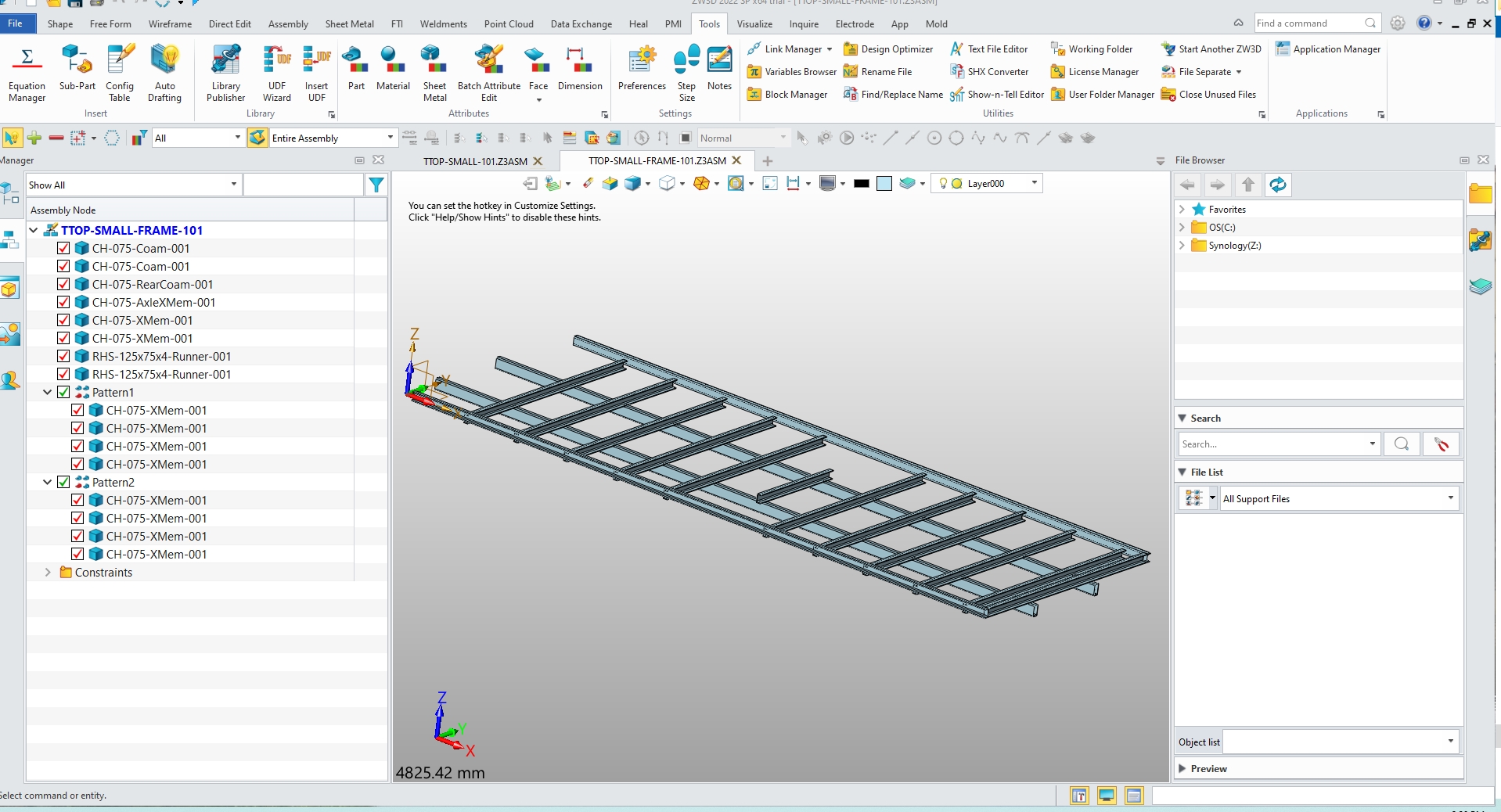

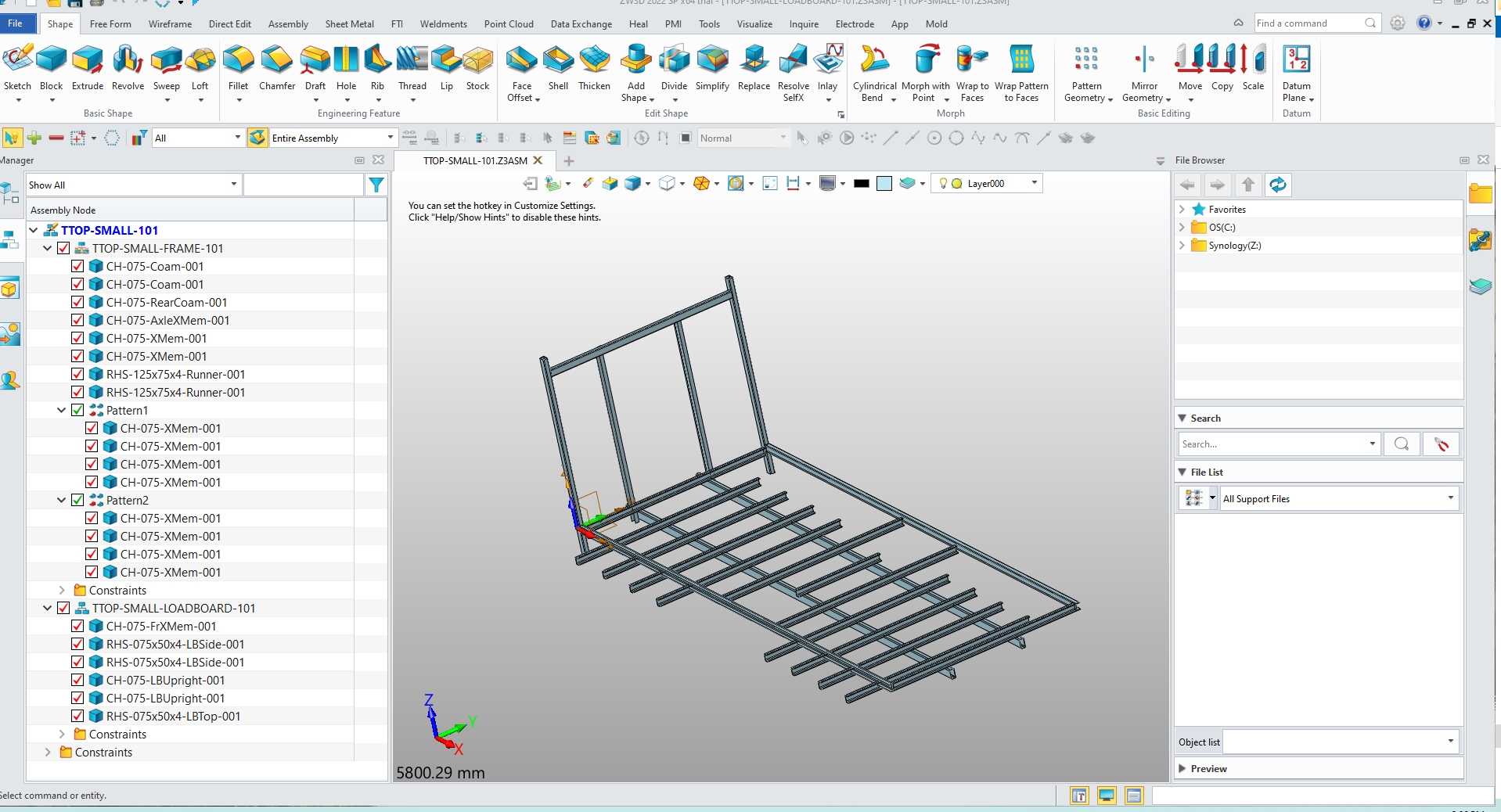

You will see from the attached file that the cross member patterns in a subassembly show up OK in the subassembly but blew up in the top assembly when the size of the truck was altered. I don’t seem to be able to fix it.

These two bodies were created from one top assembly by altering the body length, body width, rear overhang and load board height in the top Equation Manager. All other lengths and quantities are calculated by the subassembly equation managers. The part names have meaning for body builders.

Jim

TTOP-SMALL-101.zip (798.5 KB)

TTOP-SMALL-101.zip (798.5 KB)

I had to convert the pdf drawings to jpg to up load them here. I built the 4250x2100 Tabletop then changed the parameters to get the 5800x2150 tabletop which blew up in the assembly. As I kept only the pdf drawing files, I cannot go back to the original model but could recreate it as Wayne says by copying the top assembly to a new file name. I will see how this goes now that I have a sort of working model.

Jim

Wayne

I try not to use configurations in subassemblies as ZW3D is not good at updating the parts two levels down without some prompting which I am trying to avoid to reduce errors. As the relationship between assembly and path is two way, the part gets paramaters from the assembly, assemblies cannot be divorced from their parts without losing their parameter information so parts and assemblies must be archived together in such a way that the part and assembly numbers do not have to be changed. I have built models with configurations in a 3 level model but they are not quick to update as you must open every assembly and subassembly and sometimes the parts to make sure that every configuration has updated. Updating all parts in the top assembly has not been foolproof. Packing a snapshot into a zip file in a job folder may work but you would have to be very careful not to have two jobs open at once or you might not know which one you were looking at.

Jim

In a couple of hours I have created 3 versions of my tabletop, made jpgs of the drawings and packed the model as a zip file into one archive folder for each version. The patterning behaved properly after I rebuilt it once. I was using config names to tell the fabricators where the pieces went, but as Paul said, they were a pain in regenerating the models so will be abandoned as much as possible.

Jim

hi Jim159:

Thank you for your patient preparation. This is a big project, ha ha! Wait until I study the project first!

感谢你耐心的准备,这是大项目,哈哈!等我先研究下项目再说!

HI Jim159:

I’m sorry. After my attempt, it won’t refresh automatically. Maybe there will be big changes in the next version. Let’s look forward to 2023!

很抱歉,经过我的尝试,它确实不会自动刷新,也许可能在下个版本会有大的变化,我们一起期待2023吧!

Hi Liangfen. Too bad your idea did not regenerate easily. I will have a further look at using configurations in single object files with fewer layers of subassemblies. This keeps the part number count down but we still have to prompt the configuration regeneration in subassemblies.

Jim