Article is courtesy of Sam Liu, CAM Engineer at ZW3D.

Due to Forum limitations for Posts this is the start

See the whole article here

Full Machine Simulation: Nip Risks in the Bud

Feb 2020 - 4 min read

[  ](javascript: void(0)

](javascript: void(0)

If you are working on CNC machining, especially 4-axis to 5-axis machining, the red button is the last thing you want to press on, as it means there is something wrong in set-ups and you need to find out the problems before restarting machining. The results can be a waste of raw materials, production cycle time and even machine tools, undermining the production efficiency and reliability. Seldom manufacturers can bear it in today’s fierce market competition.

Figure 1. The red button to stop the running machine

How to use Full Machine Simulation in ZW3D 2020?

Are there any Tutorials on setting up a new machine definition for full machine definition, and does it simulate the actual posted code?

Hi Gerard,

not sure about a tutorial, suggest you just try. As far as I can see it is conversational.

Yes, uses GCode, no point otherwise.

Cheers

Paul

Hi All,

it is not super clear in ZW’s communications but the Machine Simulation is actually a licensed plug in you will need to buy a license for.

This means contacting your reseller for a quote etc.

Cheers

Thanks Paul,

I will look in to it, from the picture it looks very similar to Moduleworks,

and it just simulates kinematics, and not posted G code.

This is from their website,

Pasted Content.

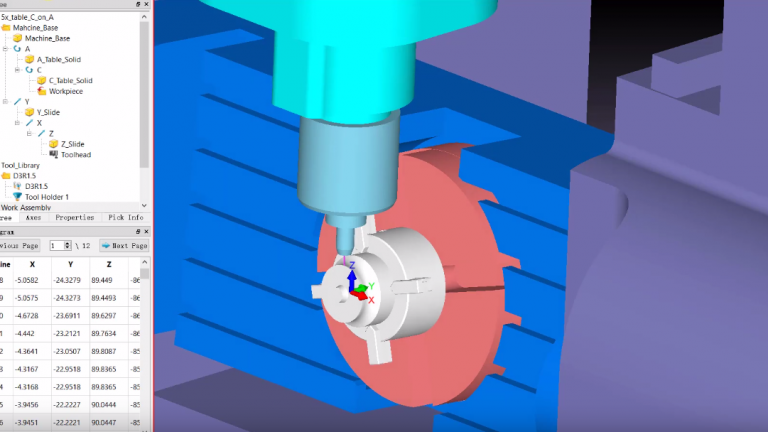

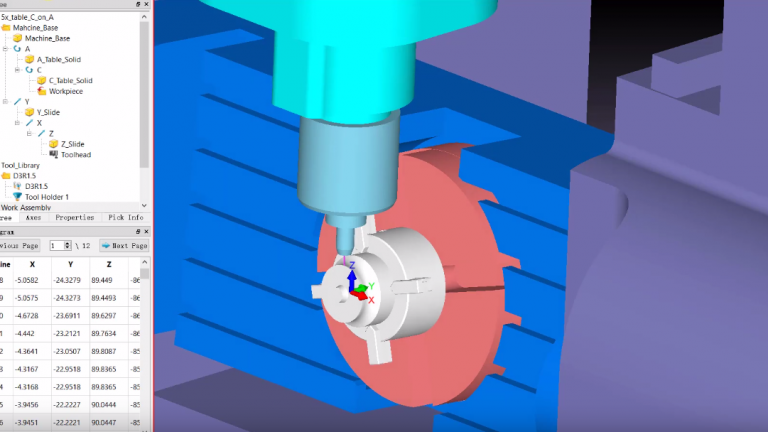

The machine simulation component offers high-performance toolpath simulation for milling, turning and combined mill-turn applications with full machine simulation. The full kinematic machine builder can simulate an unlimited number of axes which means it supports a wide range of different types of machines. Collision detection lets you correct the toolpaths prior to NC code generation.

Hi Gerard,

this is from the ZW article…

Cheers

Paul

Thank you Paul,

Well that great! This is a big deal as Moduleworks which is built into the likes of Mastercam, does not simulate G Code- so a lot of people doing complex 5 axis work end up buying Vericut, Camplete etc.

Thank you again for your prompt response.

](javascript: void(0)

](javascript: void(0)