zw3d is a great parametric software, but there is a huge part of industry that zw3d misses, and that is CNC cabinetry industry .

in modern wood / mdf cabinetry nearly half of the cabinets need CNC machining specially cabinet doors, and this industry is seriously BIG, Plywood or MDF sheets commonly used to create classical and wooden cabinets and cabinet doors and interior designs ,when we want to start machining cabinet doors in terms of software we need to consider below steps ;

-

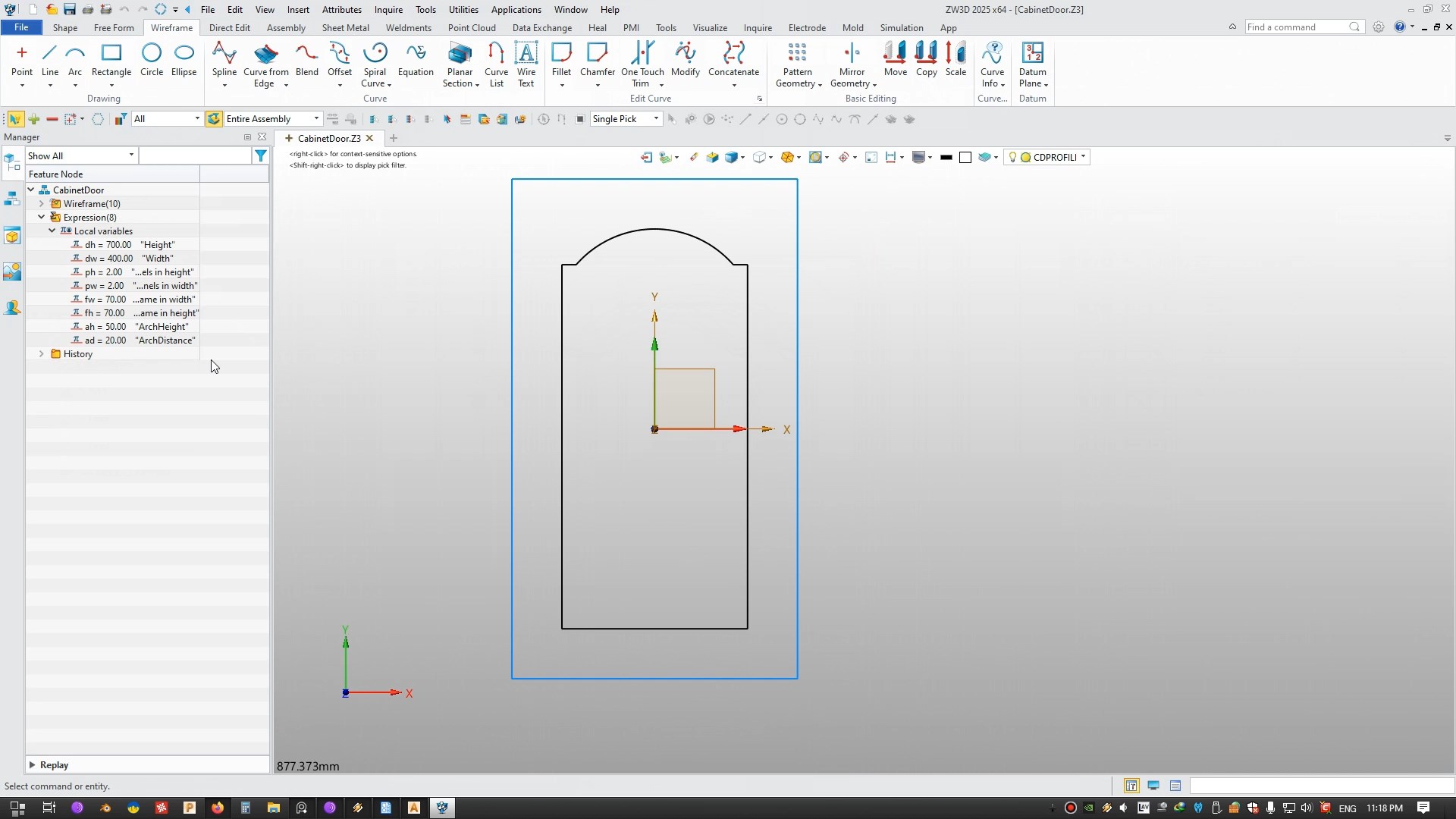

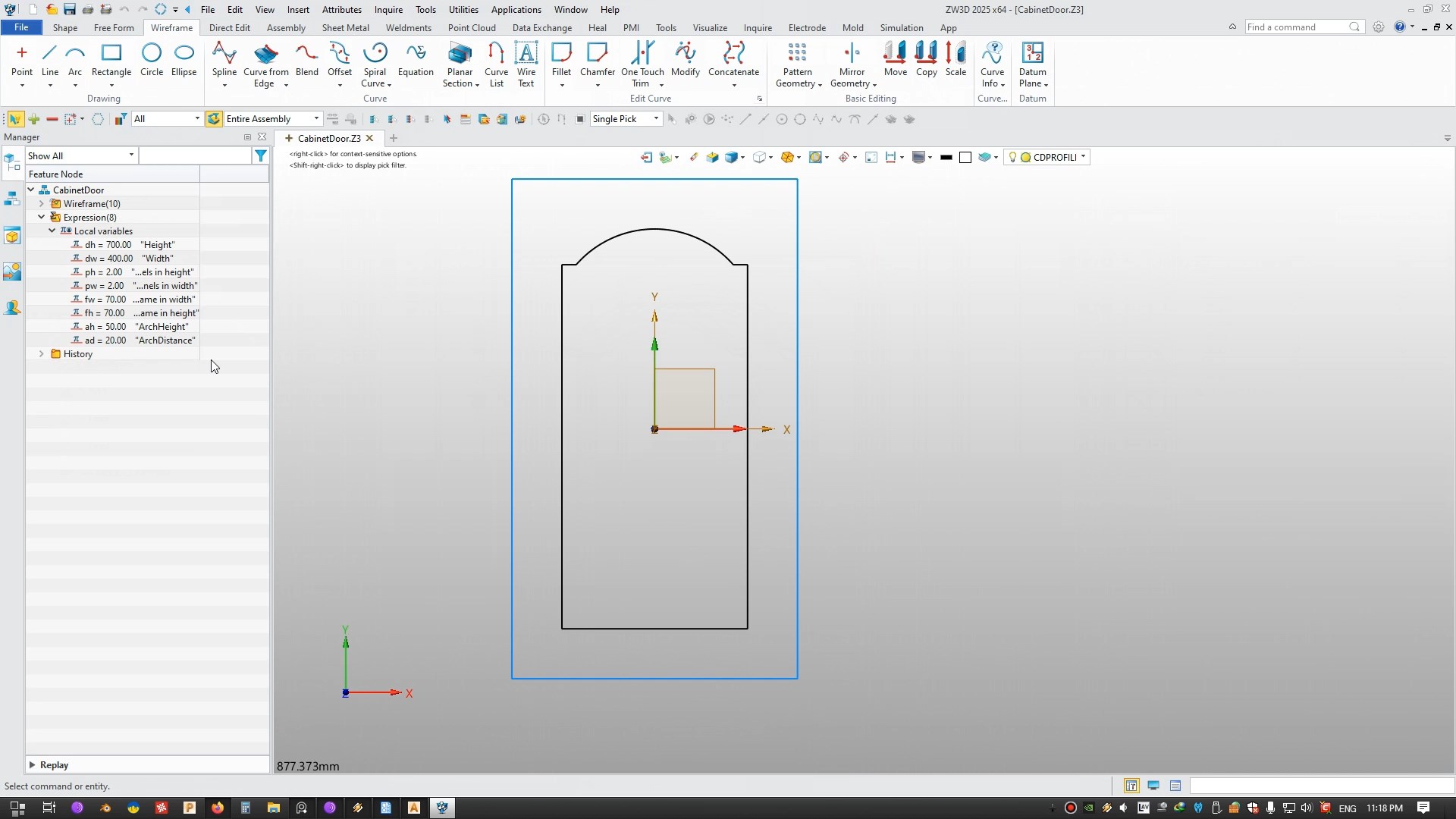

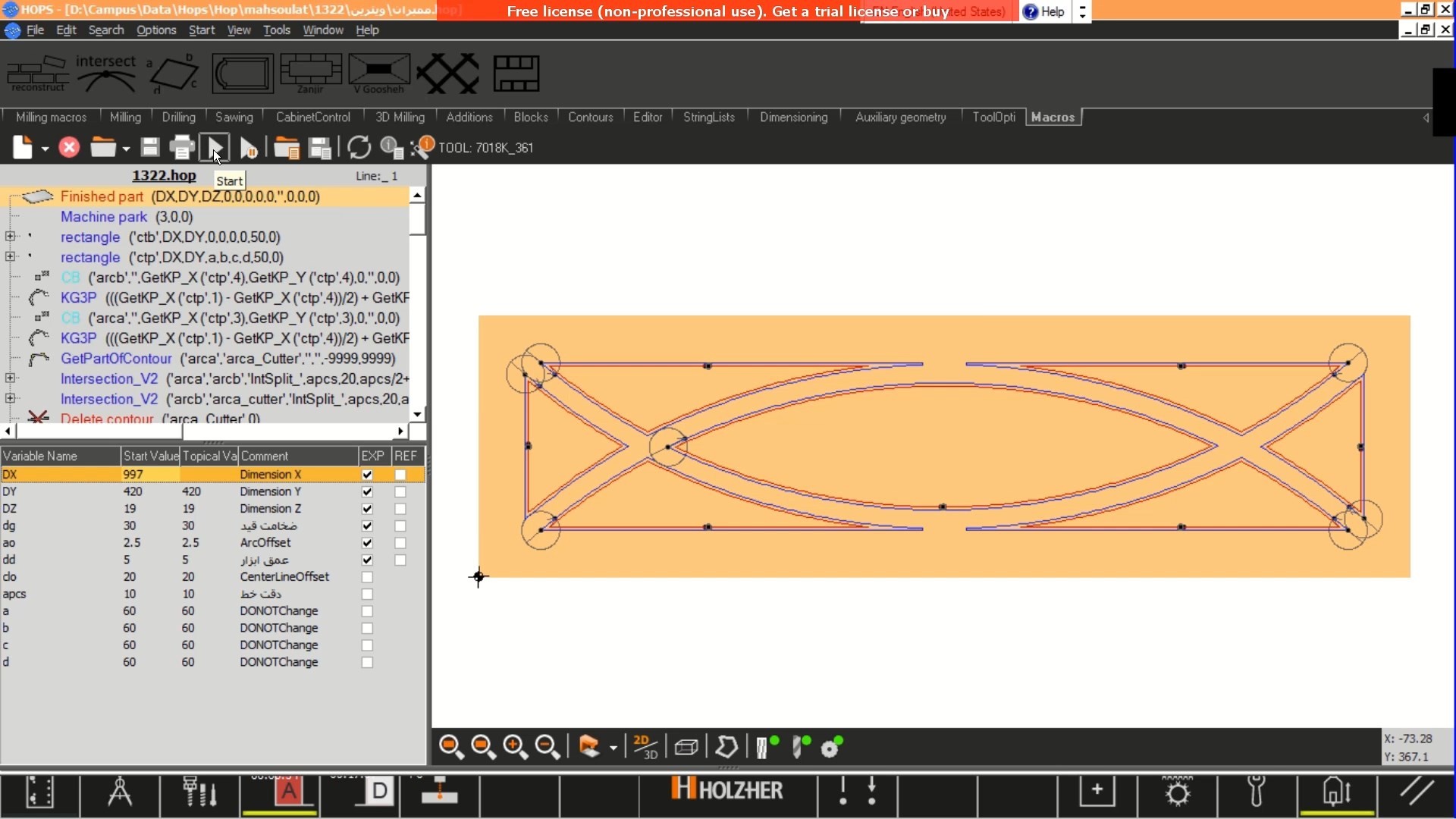

Door frames needed to be designed in a 2D drawing environment such as rectangles arches and patterns.

while this step looks like relatively simple, it becomes one of the time consuming parts of the job when hundreds of parts will ordered, while in ZW3D by using parametric modeling techniques we can achieve super fast designs with out redrawing all those repetitive lines.

(here is a demonstration video done by me) https://www.youtube.com/watch?v=JM-JD4mhEnM

-

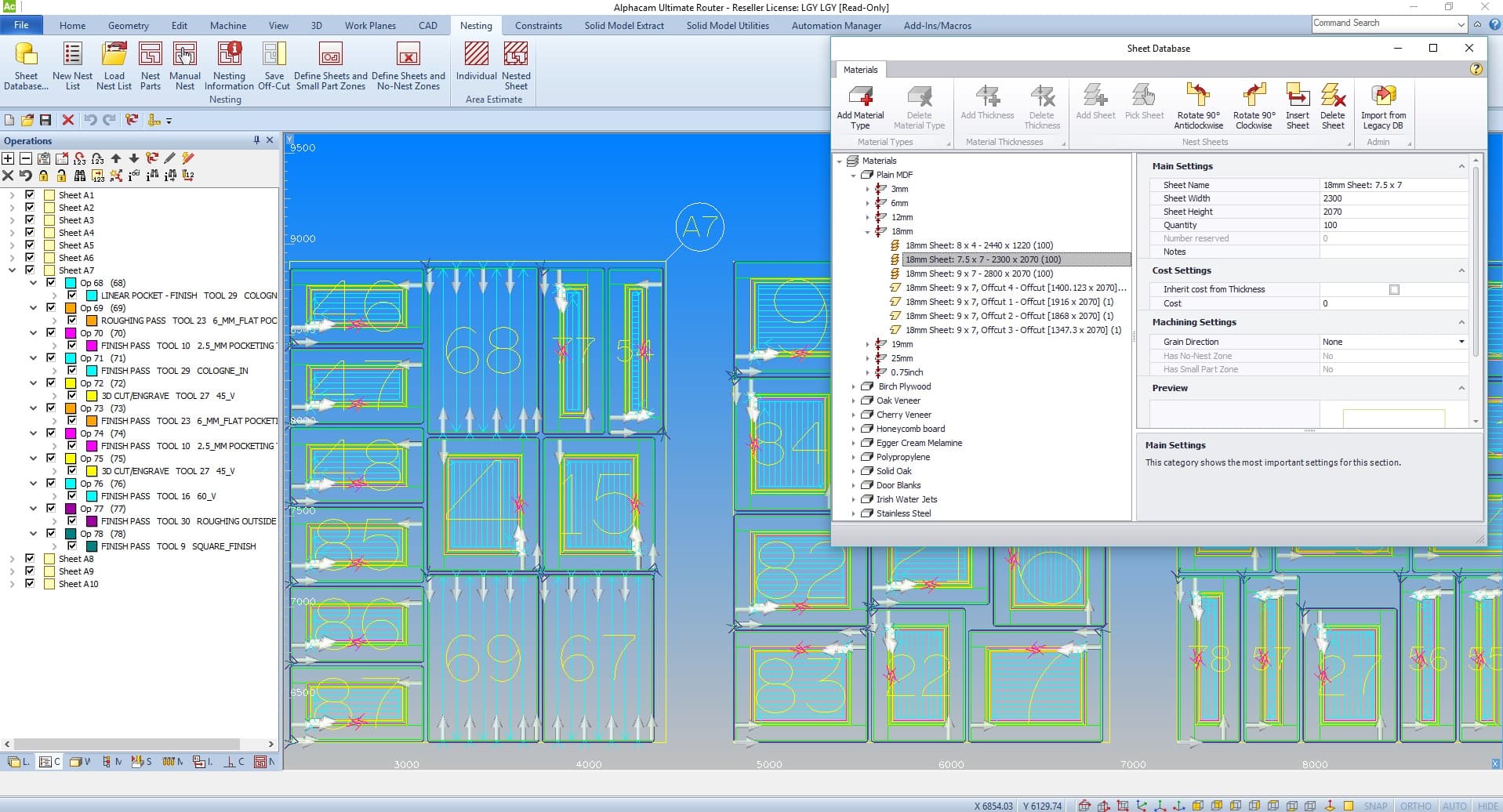

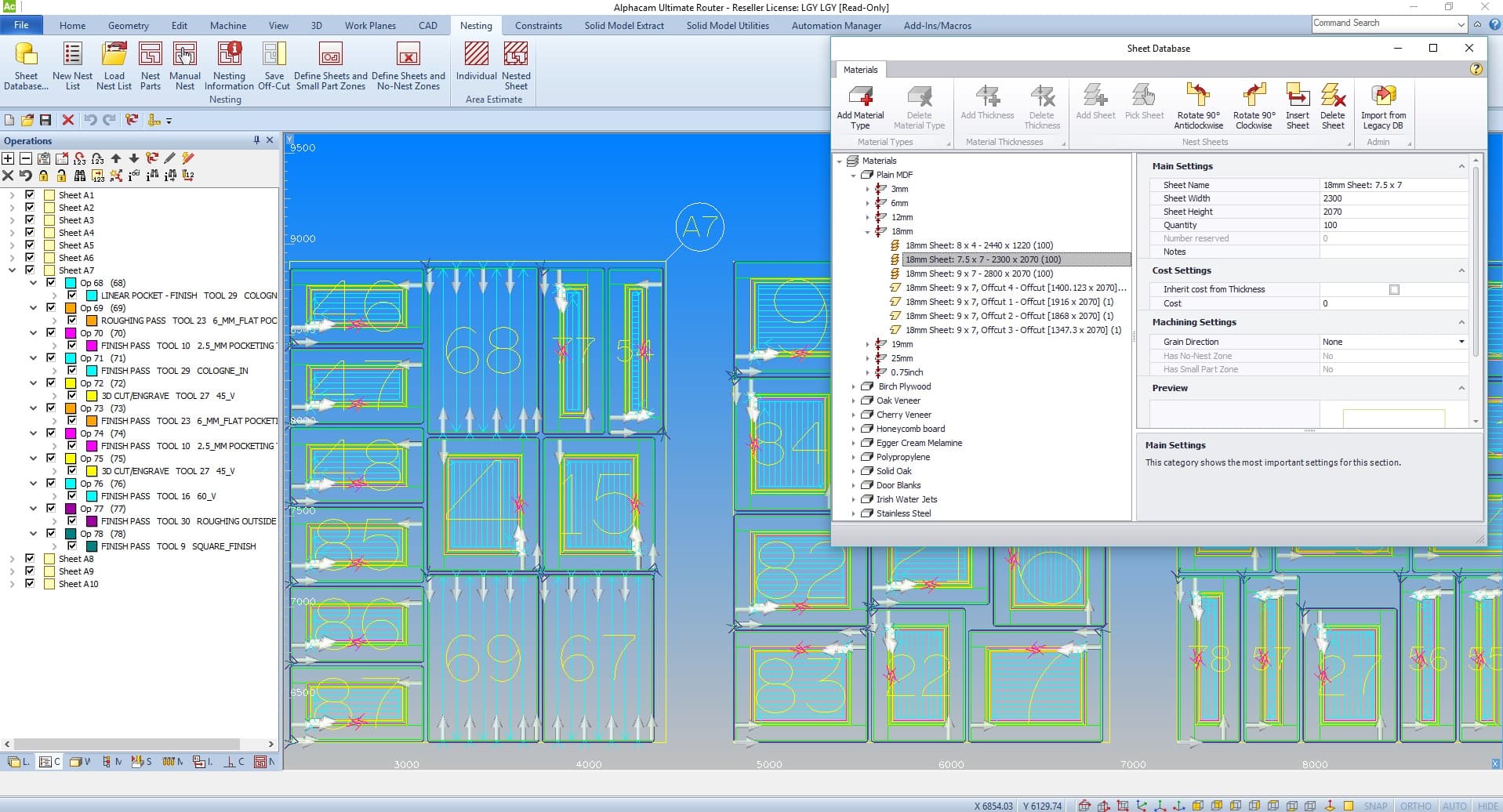

after designing the whole order list, these parts must’ve been nested in sheets for a CNC machine to cut, the nesting operation must keep all the layers intact, ( for this part of the job i use 3rd party software such as solid edge 2d nesting or mastercam software)

-

after nesting all of the designed parts its time for machining the sheets one by one, the software must’ve been able to automatically select those lines for mostly 2d machining operations and v-bit carving (or grooving) since there are a lot of layers of lines in the sheet and each one must’ve used for different operations.

Continued BELOW

ZW3D is going to be the number one software in this industry, and the win key for ZW3D are these features ;

-

ZW3D is a parametric modeling software it can easily outrun other software such as alphacam and corel draw, and autocad, since these software are not parametric and the user must’ve use VBA to benefit from parametric features which mostly are limited and time consuming and needed programming knowledge ( those softwares are industry standard for this job )

-

ZW3D is a light weight software, that can easily run on average PC, other software such as siemens NX and solid works are huge and slow in comparison to zw3d and this is a huge win for zw3d.

While ZW3D is a great tool for dealing with the design step, but it lacks the other areas and here is why:

my solution to use zw3d into this industry is to define my designs and doors as parts in zw3d library, then to use those parts in assembly with different dimensions and parameters, then export assembly as dwg or dxf first problem was layers in which the layers in part level wouldn’t follow the layers in exported assembly level which i found a temporary solution by exporting layers from part level to assembly level, in that case layers will match up corresponding to the colors of each layer , which i ran into a different problem because, back then the colors of zw3d software was limited to 18 colors which was enough for small and not complex projects ;

Continued BELOW

after exporting the assembly i ran into another zw3d flaw, NESTING, zw3d couldn’t nest those parts efficient, and as far as i know, solid edge 2d nesting can, then i used that software for nesting, but it would’ve be amazing if we had an opportunity to nest our parts, in assembly level, in a 2D sheet in the way the solid edge or alphacam or mastercam does ;

then it comes for programming these nest parts, and because of assigning each line to a defined layer i used artcam to automatically produce GCode for cnc machine, because zw3d does not have an automated machining environment as artcam does.

here is my proposal for zw3d to enter this huge industry with out competitors,

CAM environment should be able to work with parametric side of ZW3D which means for example if we have defined a 2D operation on a layer or a line or a feature of history tree in modeling section it should upgrade itself automatically, for example if we have a pattern geometry function in zw3d and increase the number of the pattern, NC code must’ve change automatically.

in assembly environment when we add those parts we should be able to go in CAM environment and regenerate those toolpaths then nest those parts ( as well as those good softwares can ) OR nest those parts inside assembly and run a batch calculation on all of those parts in the way that toolpath operations getting done in the defied order.

some of the parametric operations are not logical, such as “pattern geometry” do not work with “1” in number, one can cross all these issues, but if these getting fixed zw3d will become the N1 in this industry.

here is another demonstration video :

youtube link : https://www.youtube.com/watch?v=sk_fHLH3wns

1 Like

@hamed.desighn

HI ,Thank you for sharing this interesting project.

I have had the pleasure of working with the industry and I know that inventor/solidworks/ironcad/Topsolid. The current ZW3D is not perfect in some places, UDF also has shortcomings at present.

1 Like

@hamed.desighn

HI

I’m trying to prototype a design tool on your front end.

1 Like

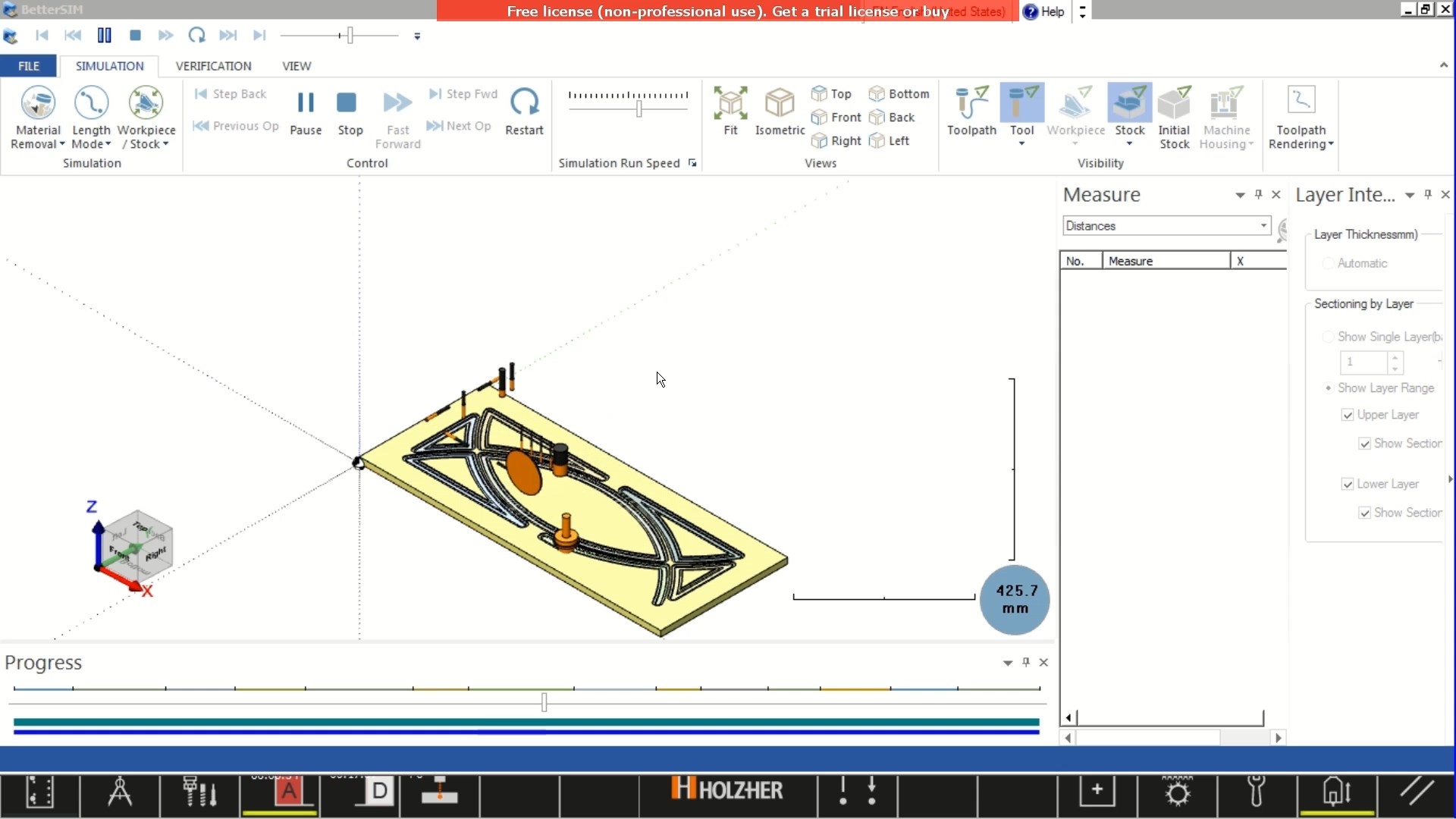

Here is a billion dollar industry waiting for ZW3D

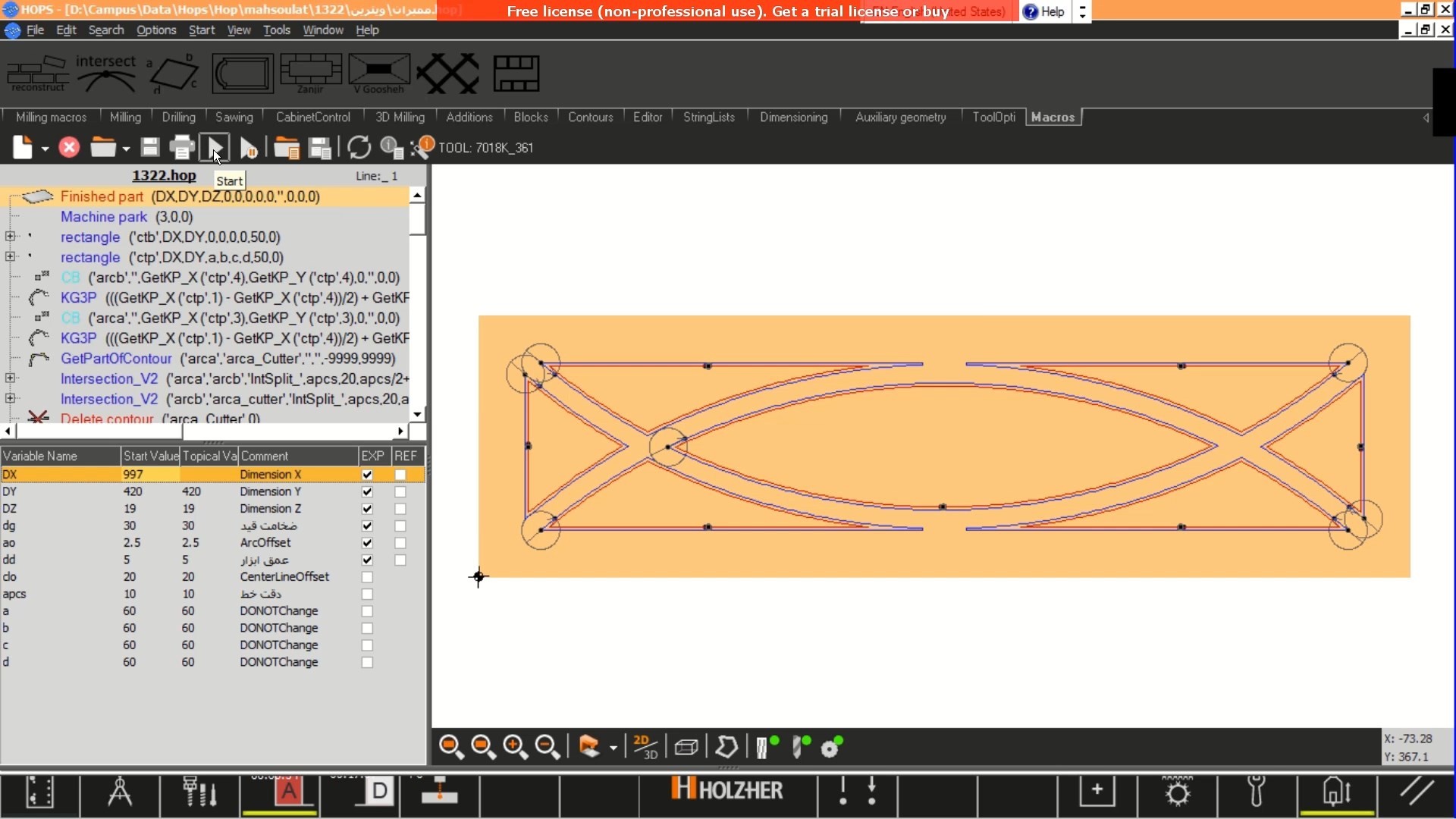

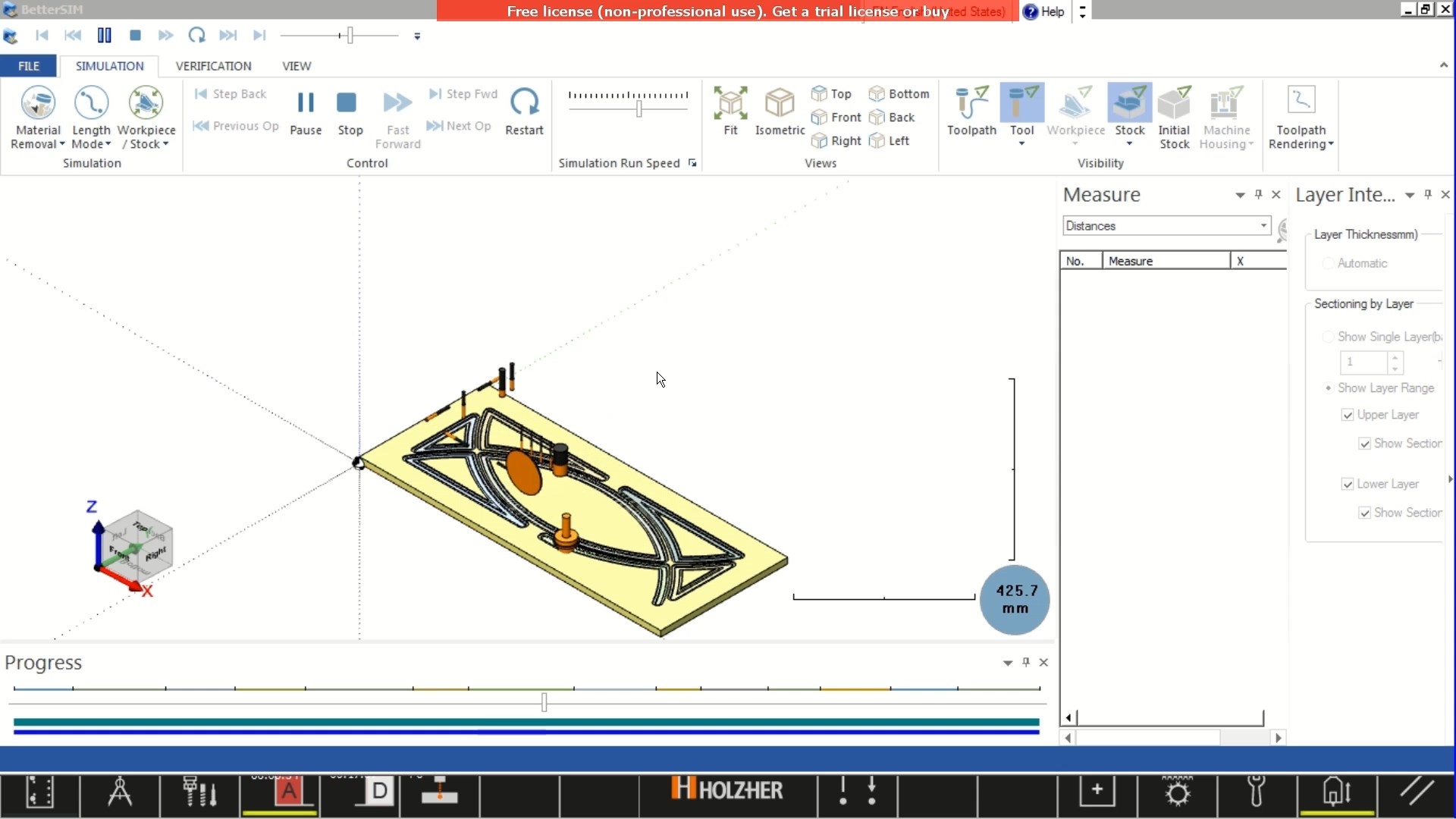

This machine is a Holzher CNC Machine, in which the operator is a normal non skilled worker with out any knowledge of computers, but this machine is far superior than the others in this industry , because of the automated design software,called NC HOPS , in which there is a parametric programming style set of features that enables this machine to output parametric stuff.

But ! i have worked and programmed with this machine for almost a decade , and my ZW3D workflow is far more better than this .

here is a Video demonstration of what this software is capable to do ; https://youtu.be/_L_5M7L5No8

I don’t know how to get in touch with zw3d developers .

@hamed.desighn

A woodworking machine comes with software?

The macro panel he brought. You developed it yourself?

1 Like

Yes, the Holzher machine Do come with their own ( custom software provided by Mastercam inc ), the point is these factories do not like to pay money to a designer, they would like to pay for non skilled workers to work for them for infinity, but there is a large opportunity for ZW3D, that i just can’t reach the developers they all seems like busy,

Infact, there is a software called ALPHACAM, dedicated only for this task,in which the operator can input an excel file for list of the sizes and types of doors required, then generate tens of sheets of GCode for their machine, but that software requires VBA ( Visual Basic knowledge ) for programming new designs ,which not many people know that.

and yes i did that NC HOPS macro

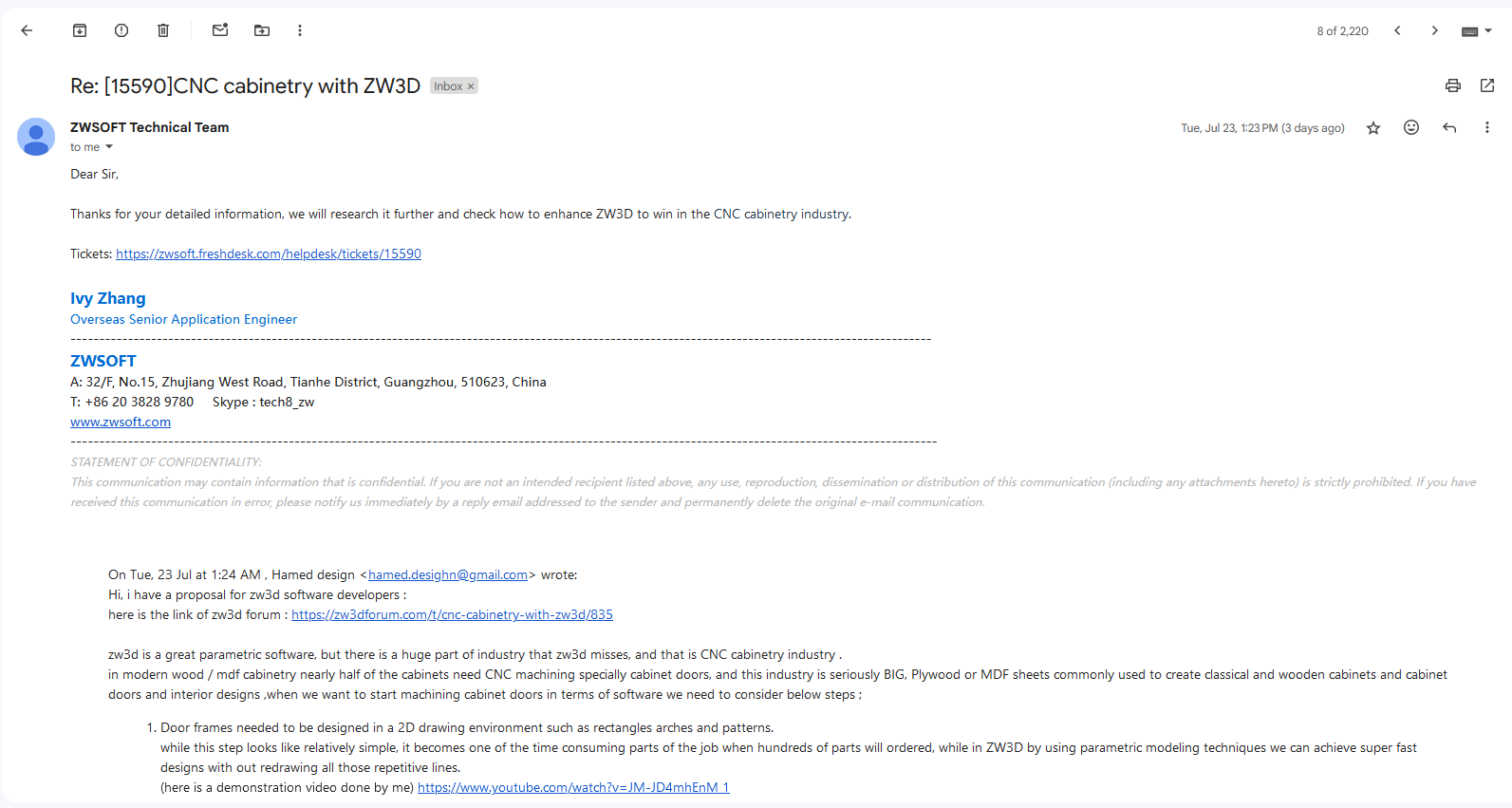

Good news !

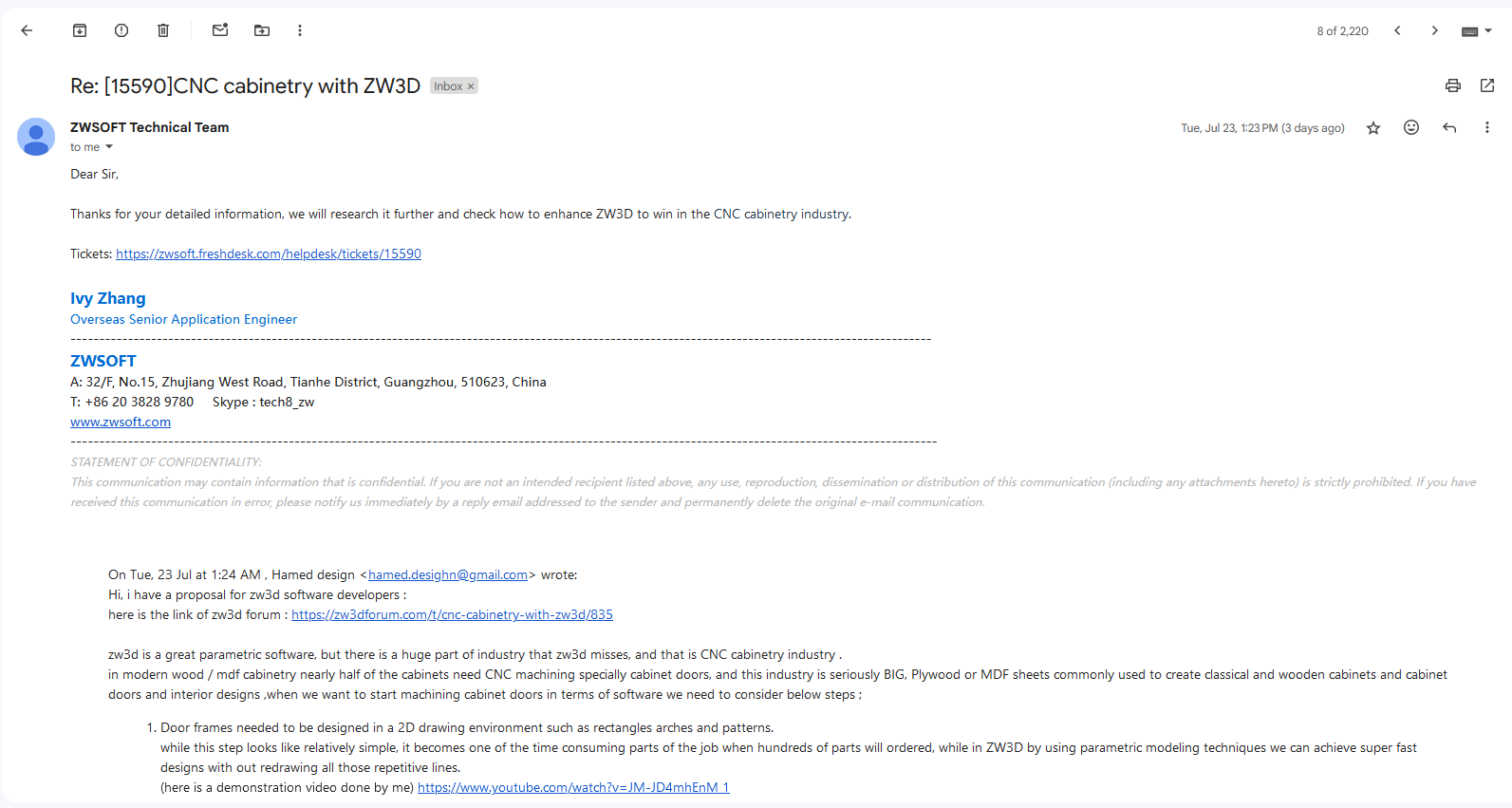

ZW3D Devs just answered our calls and their answers where positive !

Im hoping a bright future for the software !

here is the link of the ticket :

https://zwsoft.freshdesk.com/support/tickets/15590